5-step Optimization Approach Towards Sustainable S&OP Success

The previous post from our guest authors at smartPM.solutions was about S&OP maturity and the classification of your current S&OP situation according to the 5-stage Gartner S&OP Maturity Model. A correct classification enables you to highlight potential improvements to internal company processes. If you have not yet determined your S&OP maturity stage, check out our previous post.

In this post, we’ll dive a little deeper into the topic of S&OP performance and walk you through the 5-step S&OP approach, which, according to Gartner, leads to the highest possible level of maturity. The goal is to adopt an entrepreneurial mindset, make proactive decisions and to optimally support this with a professional, fully integrated S&OP solution. The end-to-end solution increases process efficiency and transparency. Isolated decisions and interface problems are replaced by a single point of truth. All departments are able to access the same data, analyses and reports – with 100% reliability and in real time. The analysis and dashboard examples shown are from the best-practice smartPM.solutions S&OP solution based on Jedox technology (see Figure 1).

Figure 1: smart S&OP performance management approach – achieve maximum S&OP maturity

The following 5-step approach for value-oriented S&OP performance management makes it easier for those responsible for S&OP to implement step-by-step improvements within your company. The analyses shown as an example in each level have different degrees of granularity and allow for drill down and drill through approaches. The best-practice solution shown can be used quickly and flexibly adapted to meet specific company requirements. For more details on each phase, see the S&OP whitepaper.

5 steps to optimize S&OP performance

Step 1 – Product portfolio optimization based on strategic company goals

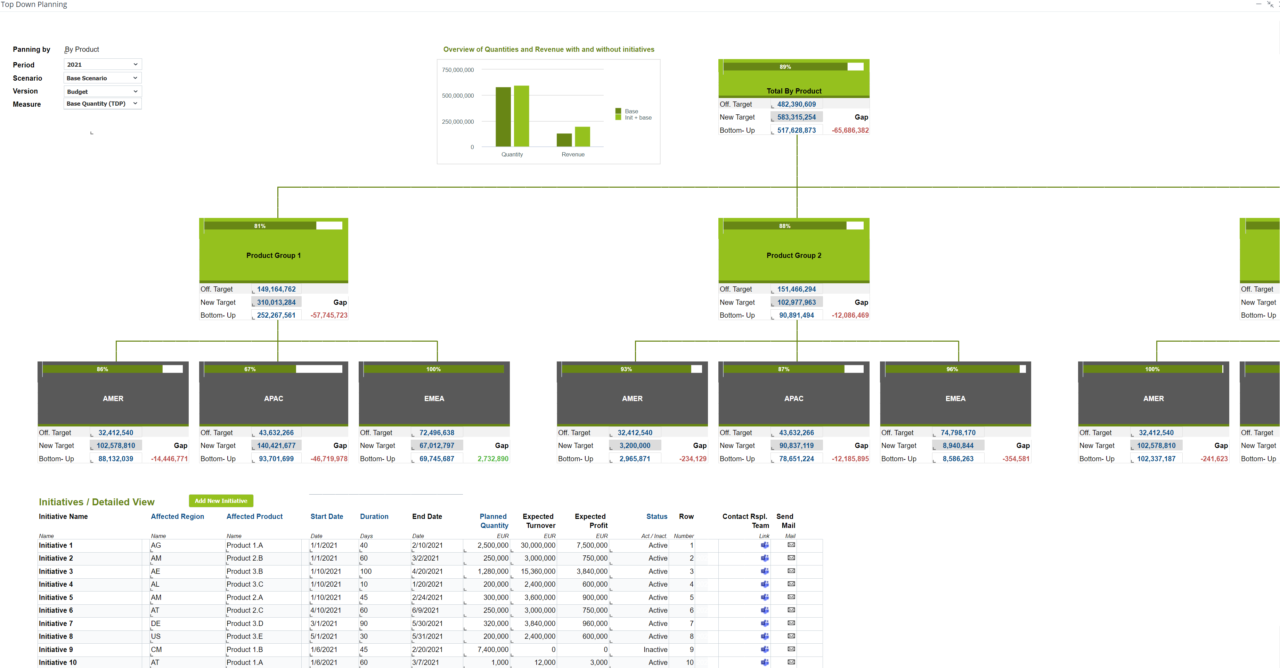

Based on the strategic corporate goals and the medium-term goals derived from them, the product portfolio can also be planned for new markets (go-to-market approach) (see Figure 2). Using top-down vs. bottom-up planning, including value driver analyses, company goals can be translated into products, markets, regions, sales channels, teams, etc., depending on the target (see Figure 3). The analyses can be enriched with local market data, such as target segment sizes, which enables flexible simulation in different scenarios for different time periods. The product library along with a display of the products in the portfolio overview provide a comprehensive, continuous overview of what the company has on offer and also make potential risks easy to recognize.

Figure 2: Go-to-market planning

Figure 3: Top-down vs. bottom-Up product planning

Product portfolio optimization is automated with optimization models, AI-supported forecasts, and portfolio scenarios. Advanced analytics with artificial intelligence allow the identification of patterns and trends in markets or in customer behavior. Historical and forecasted product successes as well as the product life cycle, product key figures, dependencies and influencing factors are also included in analyses and forecasts.

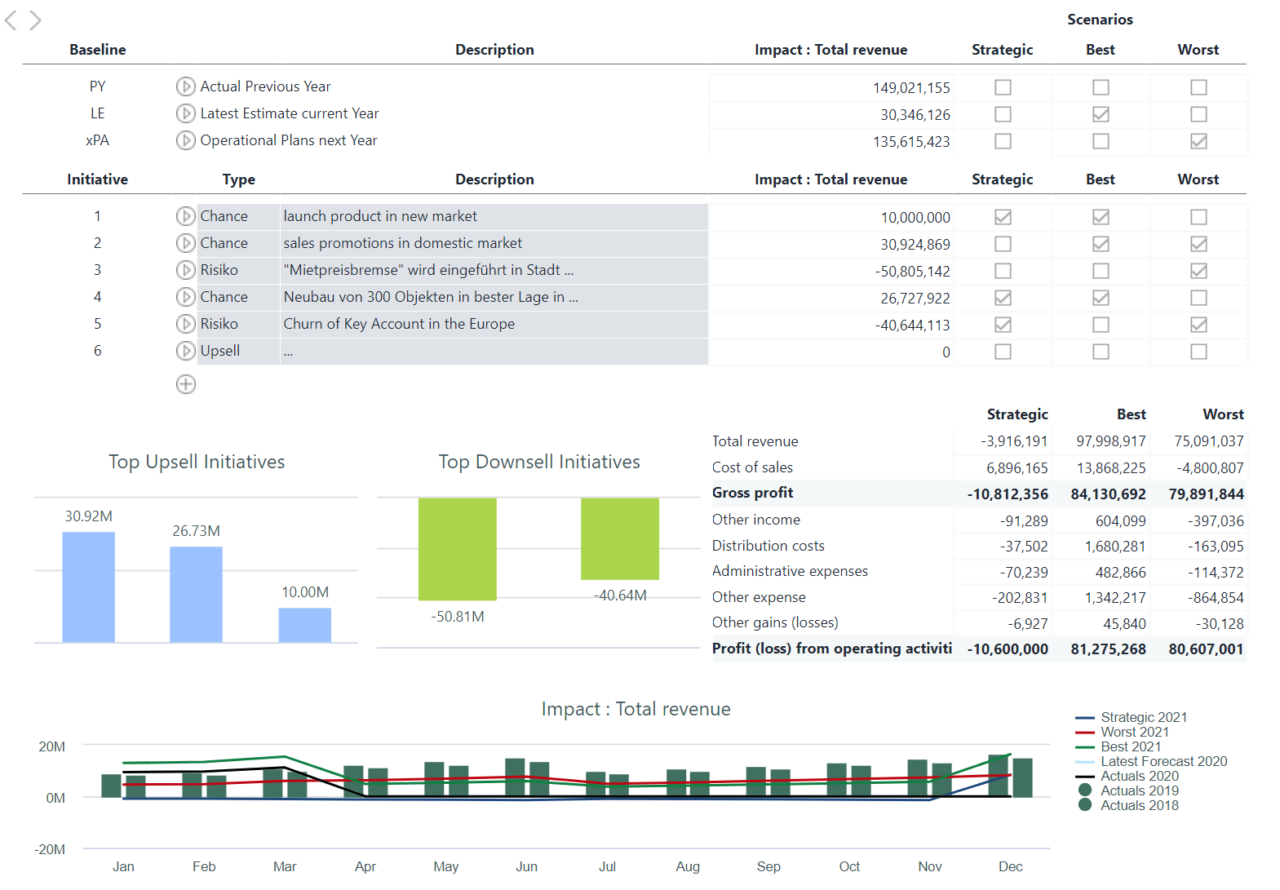

If measures, such as the development of new products for a market or product elimination, are to be integrated into the product portfolio, they can be simulated by analyzing the effects on the company’s results before they are implemented (see Figure 4). Initiatives that have been set are recorded directly in the system, where they can be traced and continuously tracked with the integrated initiative tracking. The direct assignment of initiatives to those responsible is carried out using fully integrated communication and collaboration tools (e.g., MS Teams or Planner). This ensures the implementation of the planned measures, including reminder functions.

Figure 4: Scenario analysis, impact of decisions on P&L, balance sheet, cash flow

Step 2 – Demand planning

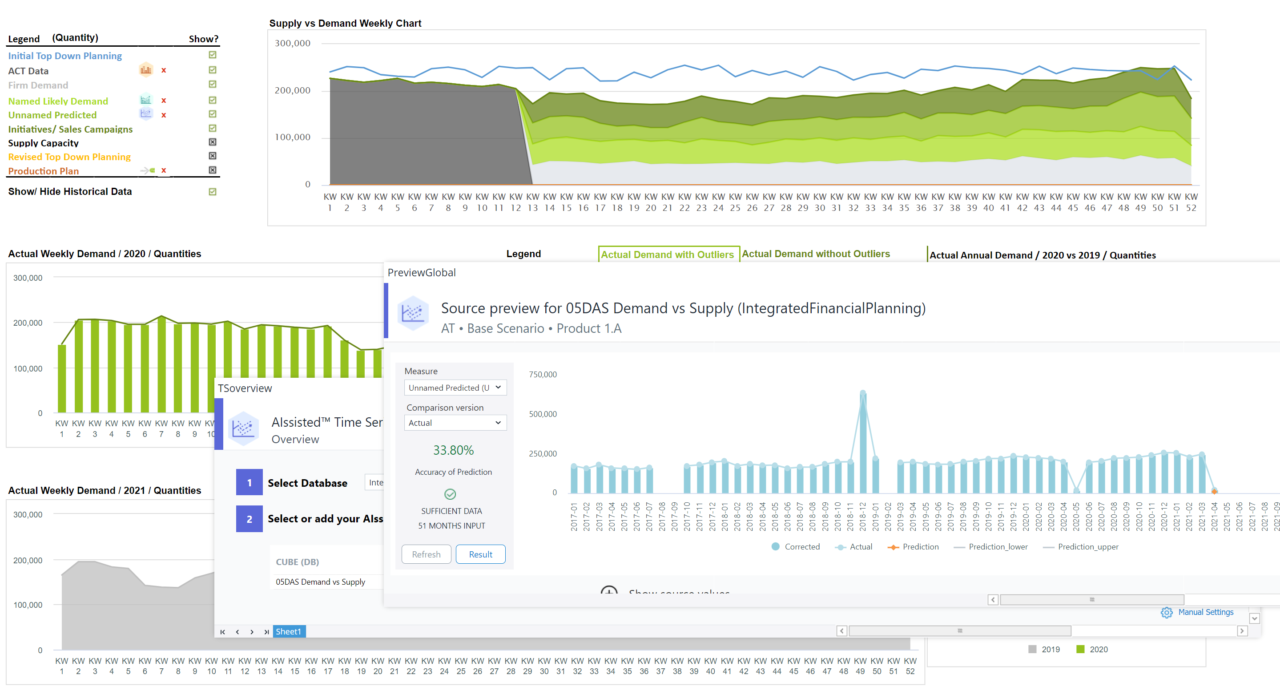

In Step 2, those responsible for marketing and sales define and link market-relevant developments within the system. For sales planning (see Figure 5), the assessment of the Sales team and AI-supported sales forecasts (see Figure 6) are used, considering numerous internal and external influencing factors.

Figure 5: Sales planning according to different types of demand

Figure 6: “Outlier control”, smoothing of data with Jedox AIssisted™ Planning

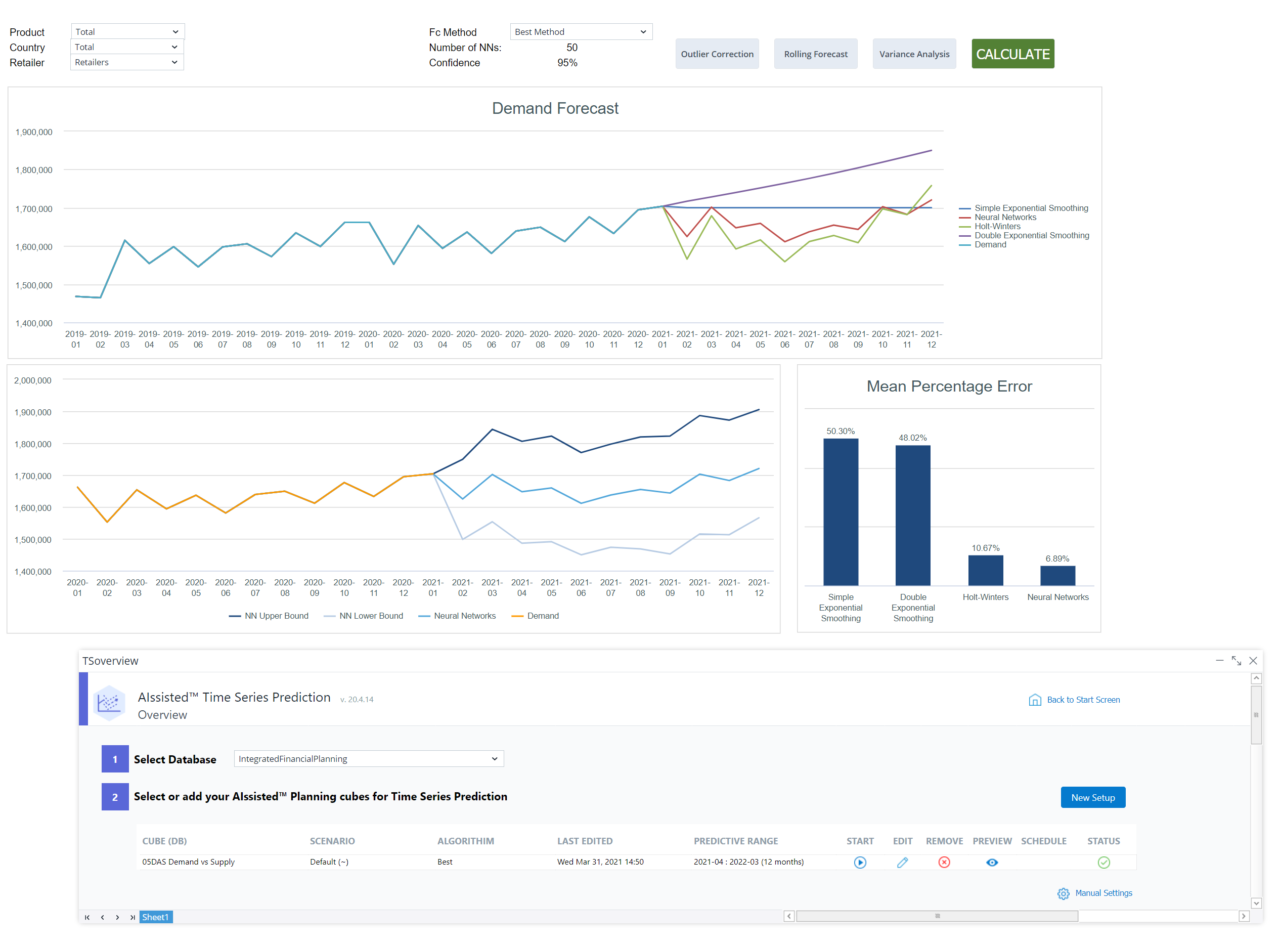

A demand plan, including a sales forecast, is drawn up for a period of at least 12 months. Integrated recommendation agents are very helpful when forecasting demand. Independent of statistical knowledge, a recommendation system suggests the best prognosis based on the error values. In the course of the demand forecast, several classic and AI-based forecast methods are taken into account. Self-learning algorithms allow the forecast values to be continuously improved to reach the highest quality. Figure 7 shows such a forecasting dashboard and details of the error values for each forecasting method. AI processes seamlessly integrated into the smartPM.solutions S&OP solution can be applied to large amounts of data and many internal and external influencing factors. After just a few rounds of learning, the forecasts can be nearly perfectly approximated to the real values. The ongoing validation of the forecasts provides additional security when making decisions. AI can also be used to improve the quality of basic data.

Figure 7: Demand forecast dashboard

Step 3 – Supply planning & supply-demand balancing

Now the product and demand planning are enriched by supply chain-related content and automatically linked to the supply plan. Storage capacity and strategy, production, logistics, and supply chain capacities are taken into account.

Possible capacity, delivery or personnel bottlenecks are also included in the planning. The supply plan is automatically compared within the system using the requirements of the demand plan. Optimization is carried out in regard to the corporate goals as well as cost minimization with high profitability and customer satisfaction. Gaps in the planning are quickly identified and initiatives are put in place with effective countermeasures. If, for example, there is a personnel, delivery or production bottleneck, a response can be made at an early stage. For instance, the production of certain products could be postponed. In the HR department, the search for personnel can begin in good time and personnel resources can be allocated, keeping in mind the relevance of the product according to company objectives. Education and further training measures are another option.

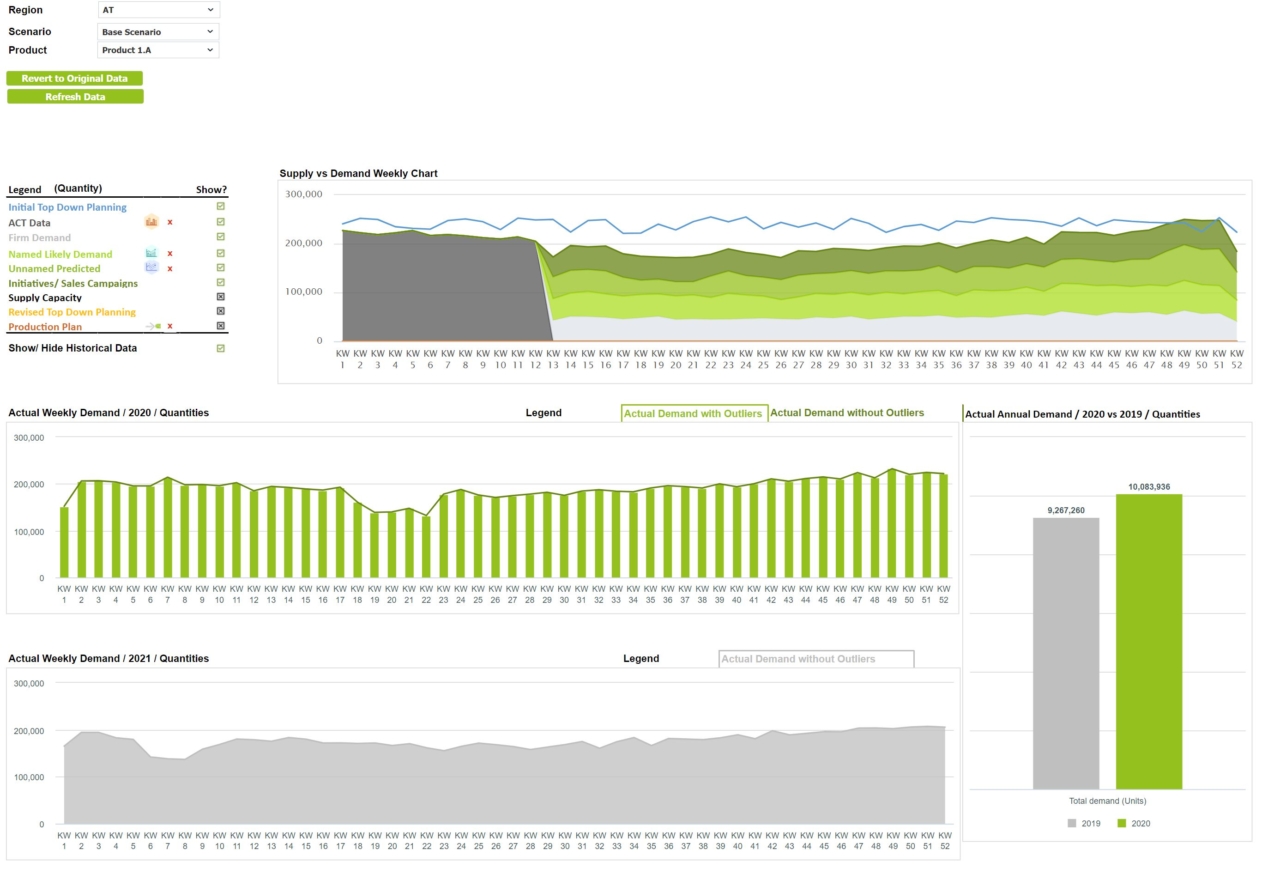

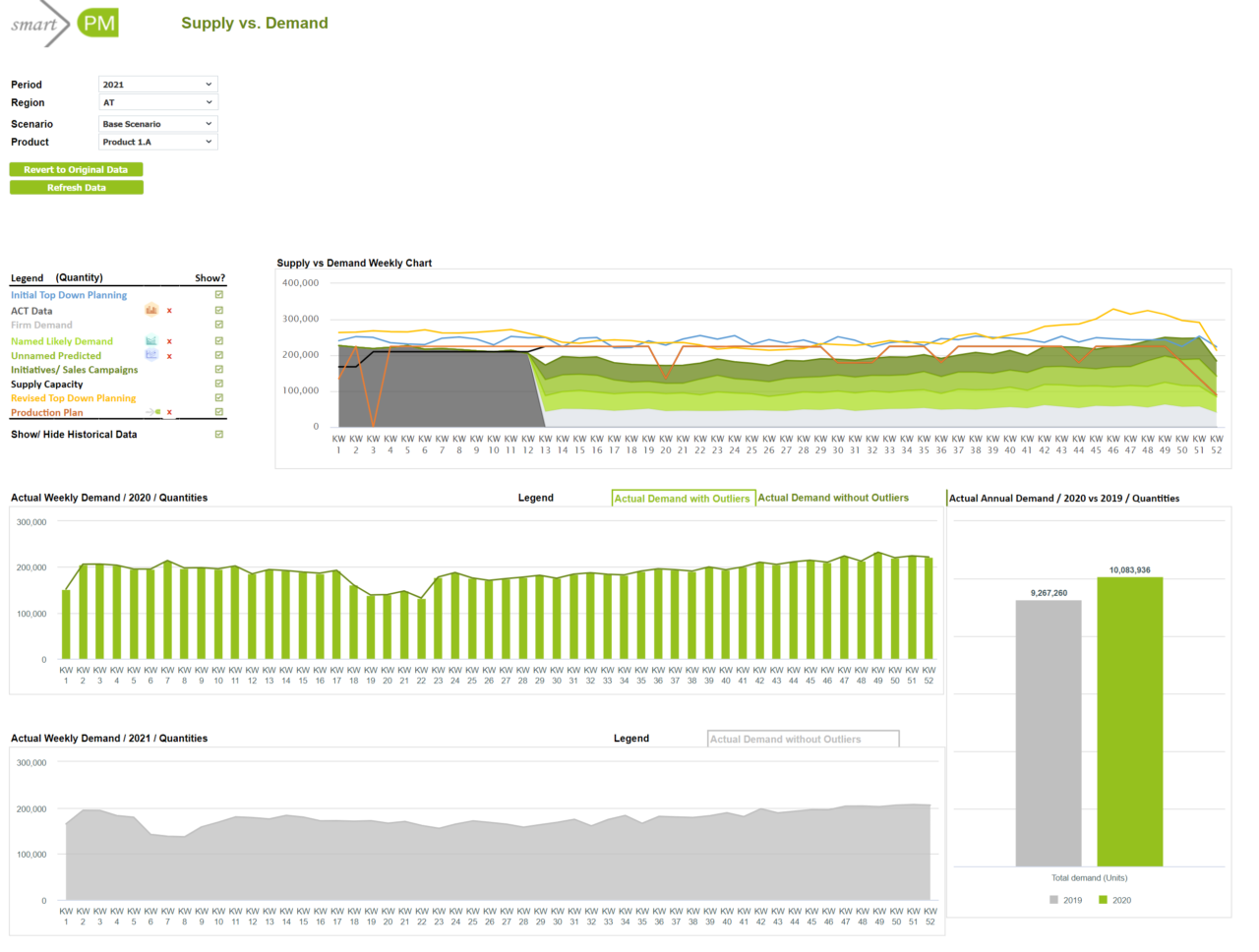

HR planning is part of the fully integrated planning model from smartPM.solutions and allows a further step towards holistic corporate management. By taking action in advance, bottlenecks can be resolved deliberately and at an early stage. Figure 8 shows you an example of a supply & demand balancing dashboard.

Figure 8: Supply-demand balancing

In this example, the expected demand (broken down according to different probabilities) is compared with the original top-down planning. If necessary, the adjusted top-down planning can also be included. Any remaining gaps can be closed through special sales campaigns; production planning is automatically adjusted through capacity expansions (such as additional shifts planned in production) or corresponding reductions.

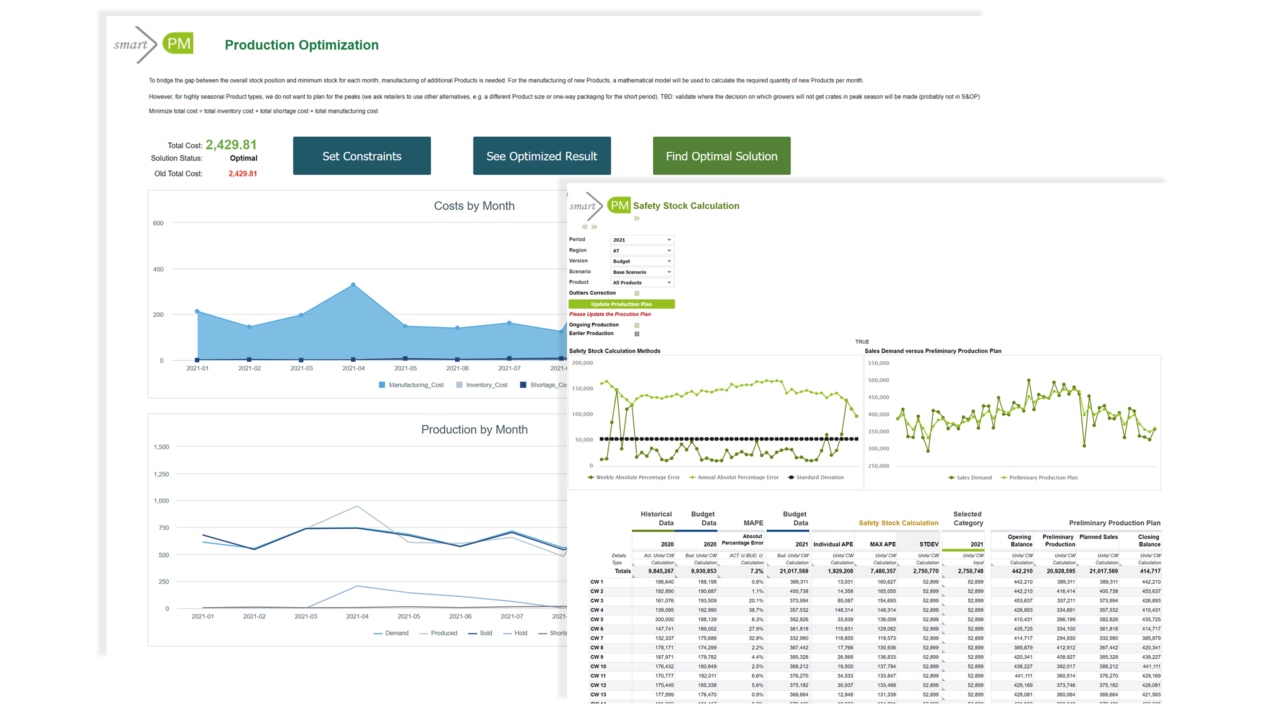

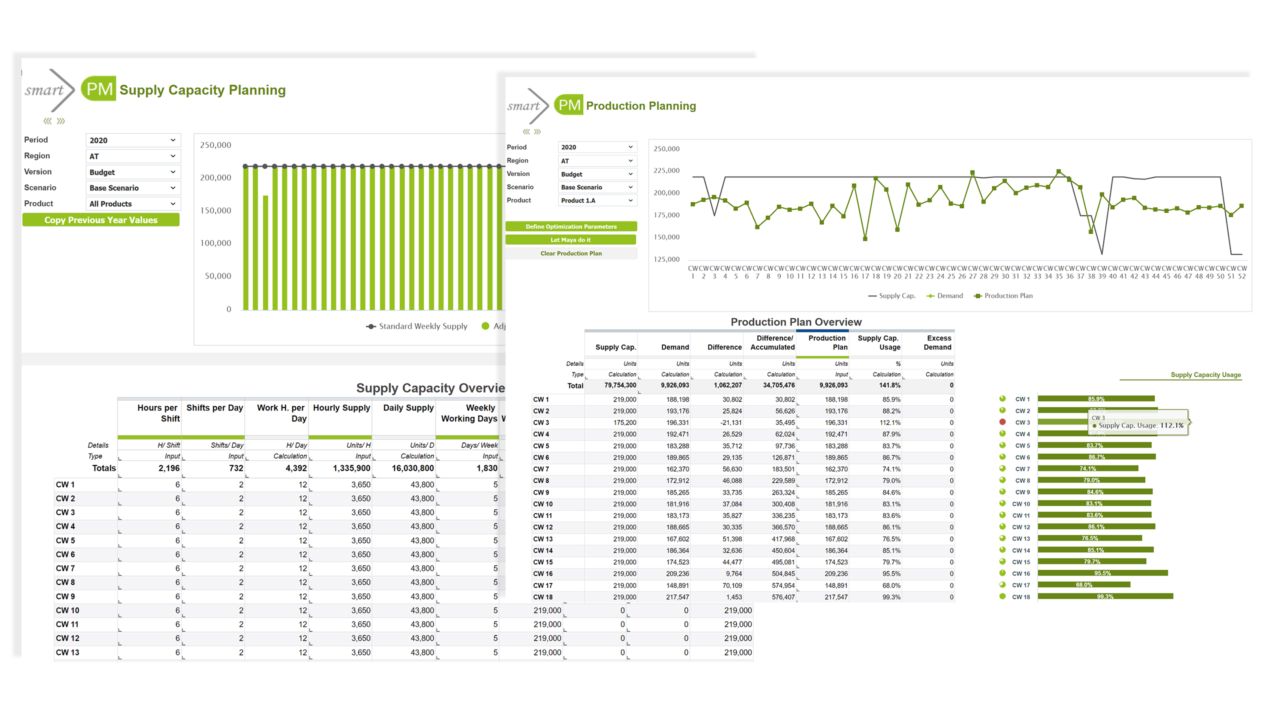

General production planning or capacity adjustments can be automated and optimized by the system, considering various constraints such as minimum stocks (safety stock). Production specifics such as molds, material availability, delivery times, etc., can also be taken into account (see Figure 9).

Figure 9: Production optimization, safety stock calculation

The system is able to bring the planned production quantities forward or postpone them, depending on how the planned order situation develops (see Figure 10).

Figure 10: AI-supported production plan optimization, support of production shifts and safety stock

Step 4 – All information is consolidated in the pre-S&OP meeting

By automating processes, the S&OP team can prepare decisions in a very focused and efficient manner for the control meetings. In Step 4, “Pre-S&OP Meeting”, those who are responsible in each department work together using the same scenarios. Proposals drawn up from all departments such as Sales, Production, Procurement, Logistics, Marketing and Finance are compiled and analyzed. Various scenarios and their effects on the company’s results are played out. Recommendations and initiatives can be tracked in the system, and corresponding roles and responsibilities can be defined. Integrated risk-value analyses make risks clear and allow them to be actively addressed or avoided. For example, staff shortages can be easily identified and averted in advance with initiatives such as training and continuing education or staff recruiting. In addition, price optimization analyses are carried out in the pre-S&OP meeting.

Depending on the corporate culture and structure, pre-S&OP meetings can take place at different management levels. In monthly meetings, which can also be held from any location with the seamlessly integrated online communication, department-specific goals are arranged according to the priority that results from the company’s long-term goals. Competing goals, such as faster delivery times for higher customer satisfaction and minimal shipping costs, are pursued in accordance with the strategic company goals. The previously defined priorities are recorded in the S&OP system and compliance with them is ensured by assigning responsibilities.

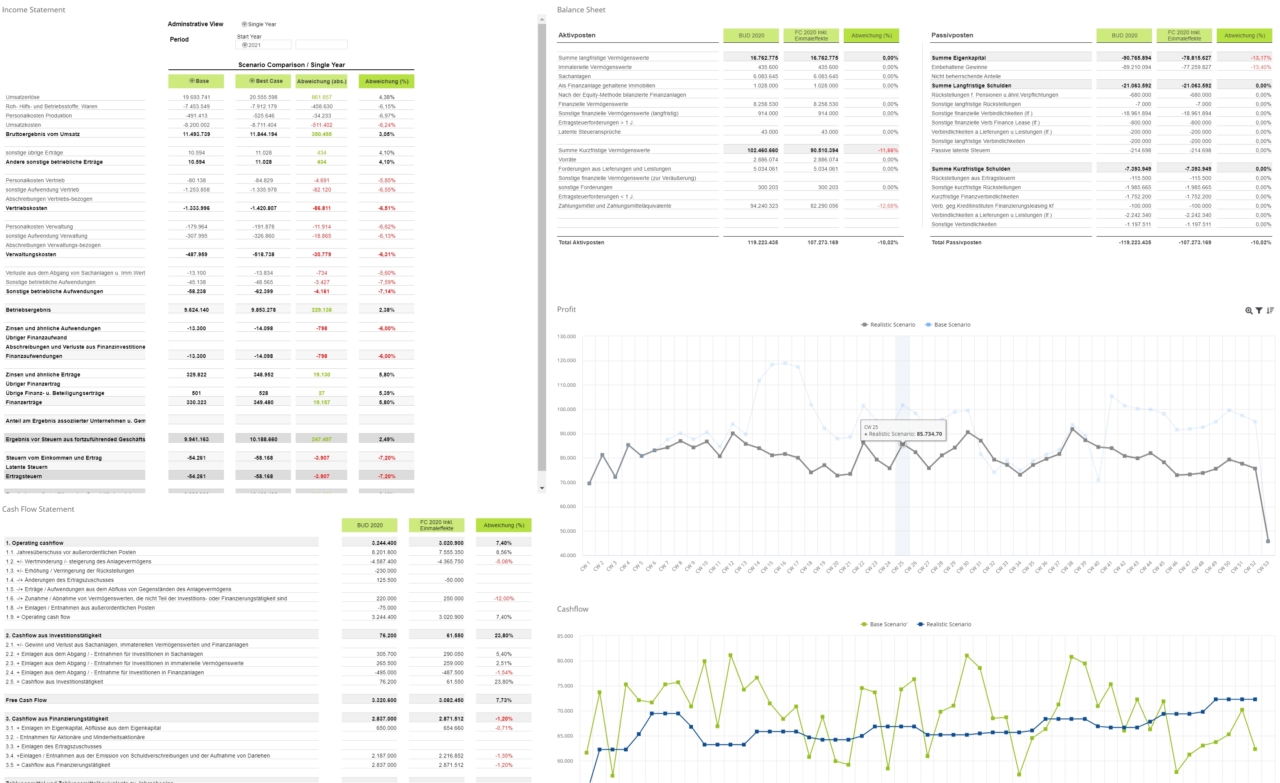

In the pre-S&OP meeting, all analyses for the final S&OP plan are compiled, various scenarios (best-case, worst-case) and their consequences, risks and opportunities are analyzed and prepared for management as a basis for decision-making.

Figure 11: Scenario comparison with impact analysis on P&L, balance sheet, cash flow

Step 5 – How do executive meetings benefit from a professional S&OP solution?

The executive S&OP meeting serves to evaluate the agreed pre-S&OP plan for decision-making in terms of the strategic corporate goals. Above all, scenario analysis, rolling forecasts, AI-supported forecasts and value driver analysis have proven value here. They simulate the effects of measures on the P&L, balance sheet and cash flow (see Figure 11).

In executive meetings, discussions often lead to spontaneous questions that need fast answers. At the push of a button, it is possible to play out scenarios that had not been previously considered during the pre-S&OP meeting. Drill-down and drill-through analysis as well as the jump to the ERP system allow ad hoc analysis at any granularity level. Adjustments to the data or specifications, e.g., from top-down target specifications, are immediately visible to everyone in the system. The results of the pre-S&OP meeting can be easily accessed in a standardized report form. This facilitates comprehensive, holistic S&OP control that aligns with corporate goals.

“It is very clear that we can now create fast and reliable scenarios in-house. The employees think in terms of variants, the data is available quickly and can also be accessed from anywhere. You can look at data together and don’t have to send an Excel list around. This leads to a very high level of acceptance and credibility. This also saves a lot of wasted time.

What we really noticed is that the focus of the discussions has shifted. We no longer discuss the formulas, but rather the recommendations for action and measures that must or should be implemented. We can generate reports without prior notice and the employees always have up-to-date data, which means safe decision-making for management.”

Arbi Araks, Head of Finance & Controlling at List CG

Learn more in our upcoming webinar on “5 steps to S&OP success”, in which numerous case studies will be demonstrated live. Take an even closer look on the Jedox Marketplace with the demo version of the best-practice S&OP performance management solution from smartPM.